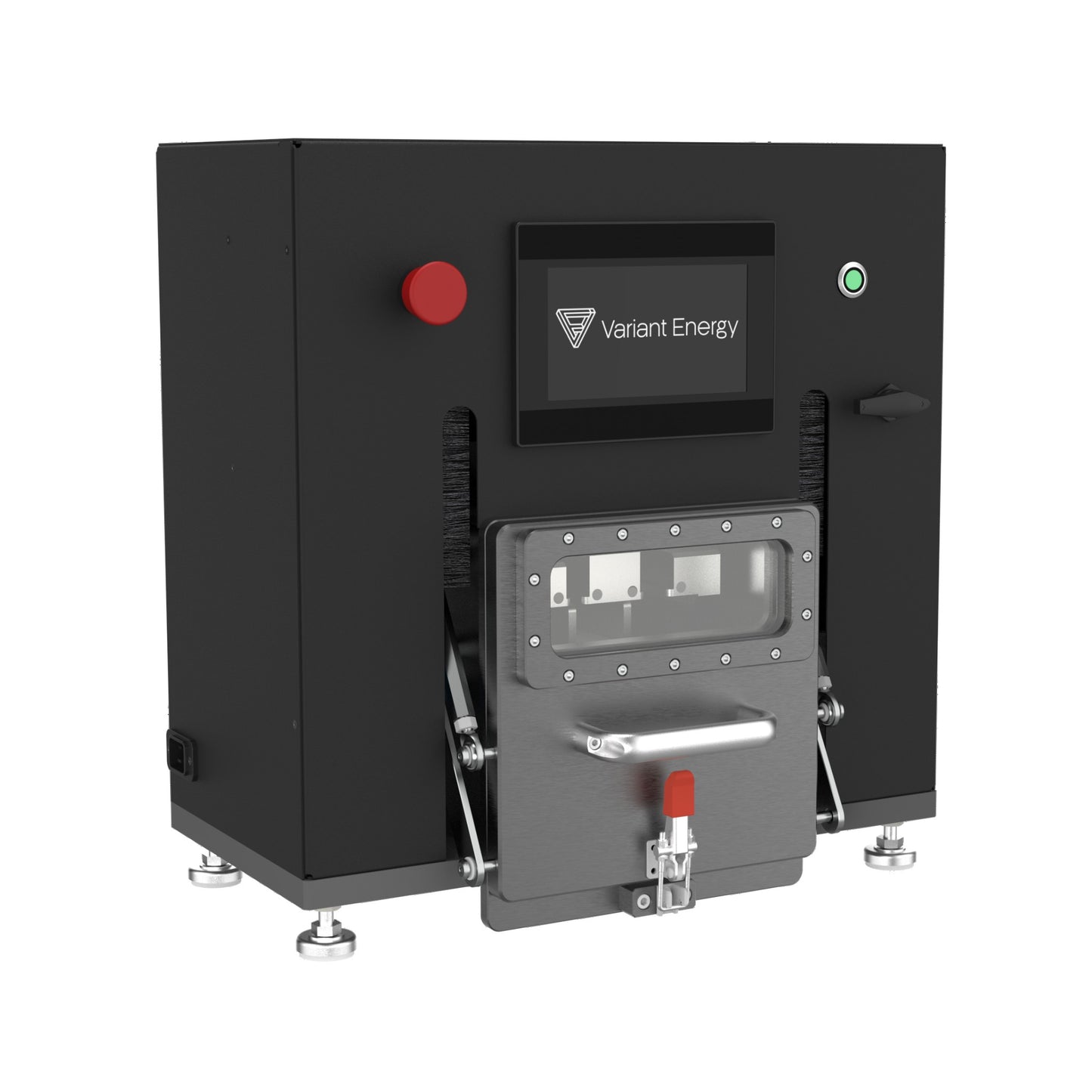

Pouch Cell Vacuum Heat Sealing Machine

Pouch Cell Vacuum Heat Sealing Machine

To enable complete electrolyte impregnation of the electrode pores, the pouch cell must be exposed to a vacuum environment and then sealed. The process parameters must be controlled accurately throughout the entire process cycle; if the vacuum vent rate is too drastic, rapid gas evolution will cause electrolyte spillage and mass loss. If the final vacuum level is too low, the volatile electrolyte additives will evaporate. The heat sealing jaws must be hot enough to create a long-lasting seal but not so hot as to boil the electrolyte inside the pouch.

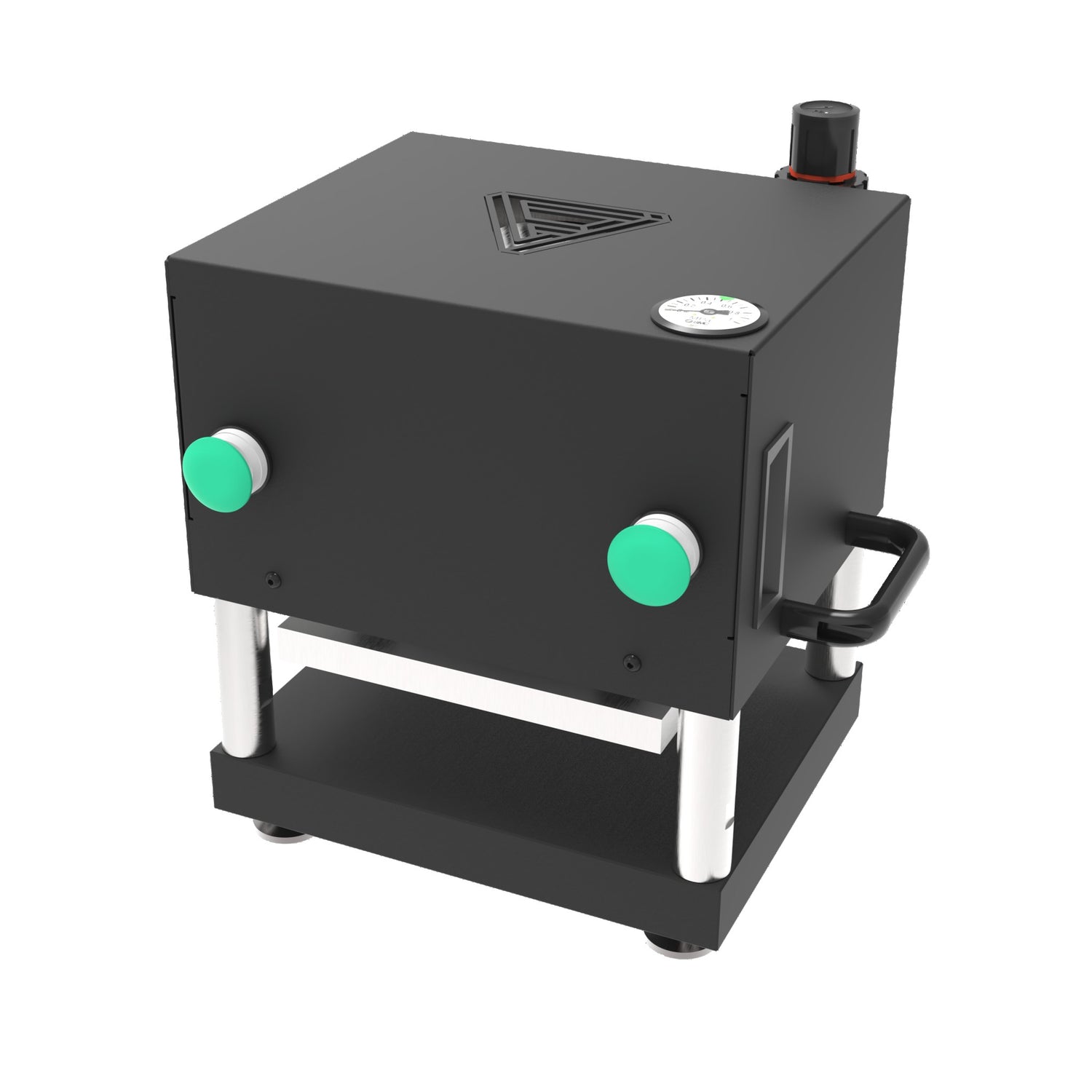

The Variant Energy Vacuum Sealer controls all of these critical parameters, which are stored in recipes accessible via the 7" touch screen. The unit has been specially designed to be utilized in a standard-size Ar glovebox.

Features

- PLC-controlled sealing parameters (pressure, temperature, dwell time) AND vacuum cycle parameters (pumpdown rate, vacuum setpoint, vent rate, cycle count)

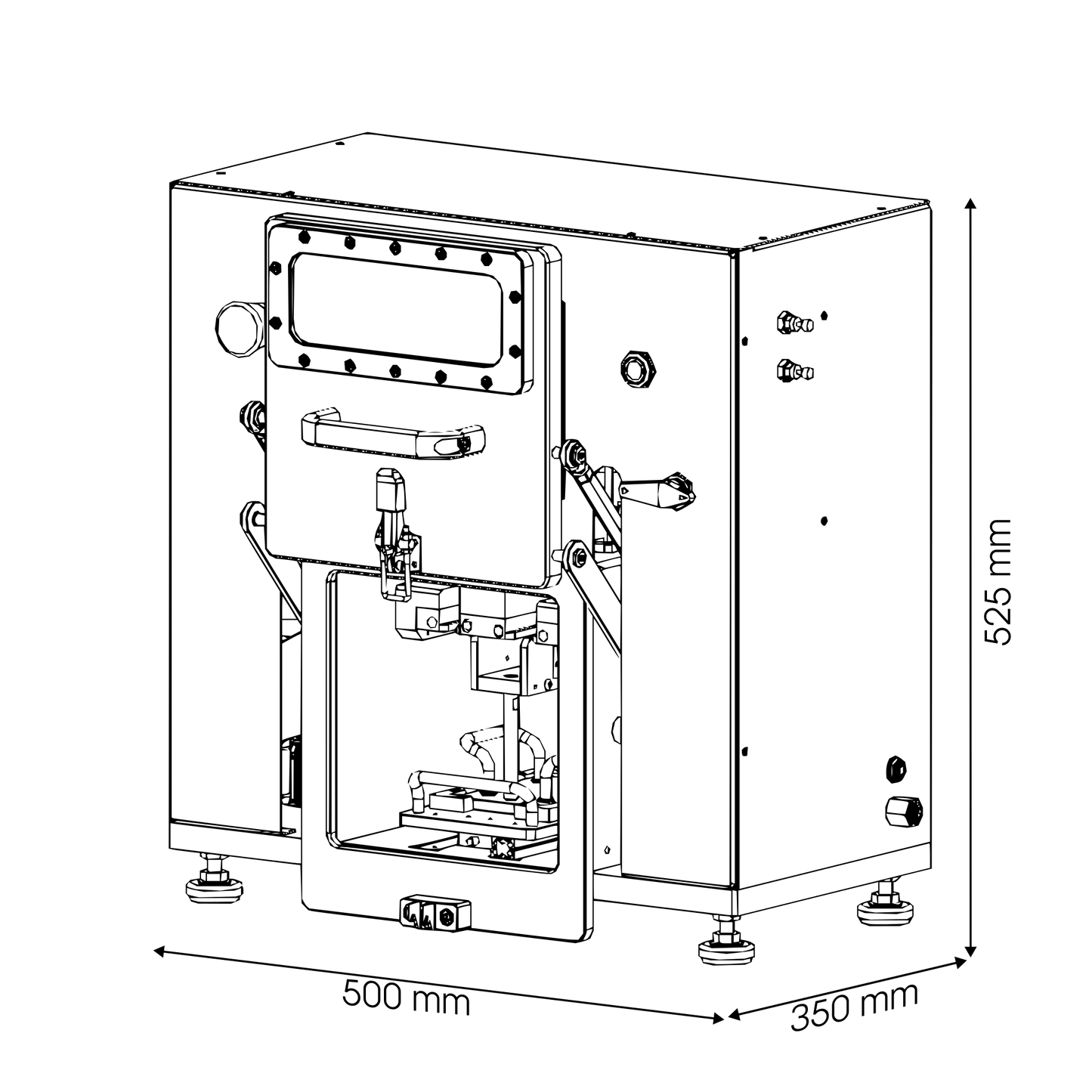

- Vertical-sliding chamber door allows for space-efficient and operator-friendly use in laboratory gloveboxes

- Jaw arrangement allows for two cells to be vacuum sealed per cycle, increasing throughput

- 7" touchscreen to view process variables, store and retrieve recipes

- Pouch jig is removable for easy electrolyte filling and cleanup

- Compatible with Ar glovebox environment

Specifications

| Temperature Control | 200°C maximum, +/- 2°C |

| Vacuum Control | Electronic vacuum regulator, 100 Torr |

| Pressure | 0.1-0.8 MPa +/- 1% |

| Jaw Material | Nickel-plated aluminum |

| Recipe Storage | Up to 99 recipes |

| Power Supply | 120 VAC, 60 Hz or 230 VAC, 50 Hz (specify) |

| Dimensions | 500(W) x 350(D) x 525(H) mm |

| Weight | 37 kg |

- Contact sales@variantenergy.co for your quote